High Frequency Technology - HiFrequency PCB

Smart Solutions for High Frequency Signals up to 77 Ghz

High frequency PCBs (hybrid build-up) are circuits for the transmission of high frequency signals up to 77 GHz with adapted design, layer build-up and material. With high-speed components and signals with very short pulse rise times the PCB becomes a component.

Applications:

- transmission of the electrical signals

- reduction of (multiple) reflections

- optimum matching of output and input impedance of transmitter and receiver

- guarantee of signal integrity

- increase in signal transmission speed

- electromagnetic compatibility

Advantages:

- excellent mechanical characteristics

- coefficients of expansion adapted to copper,

- stable dielectric constant

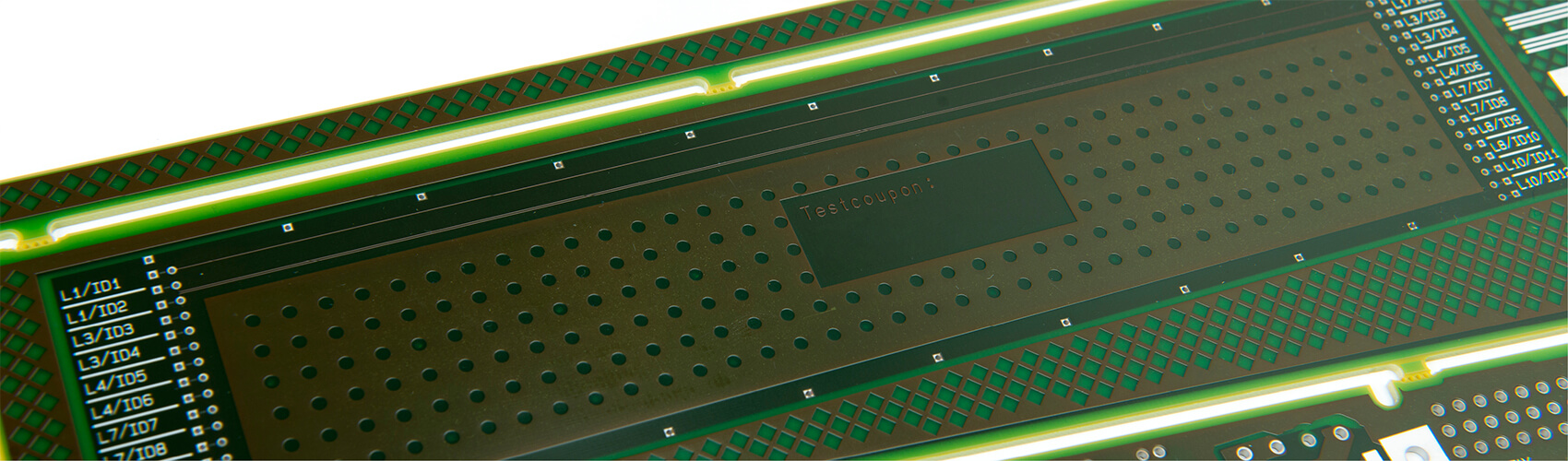

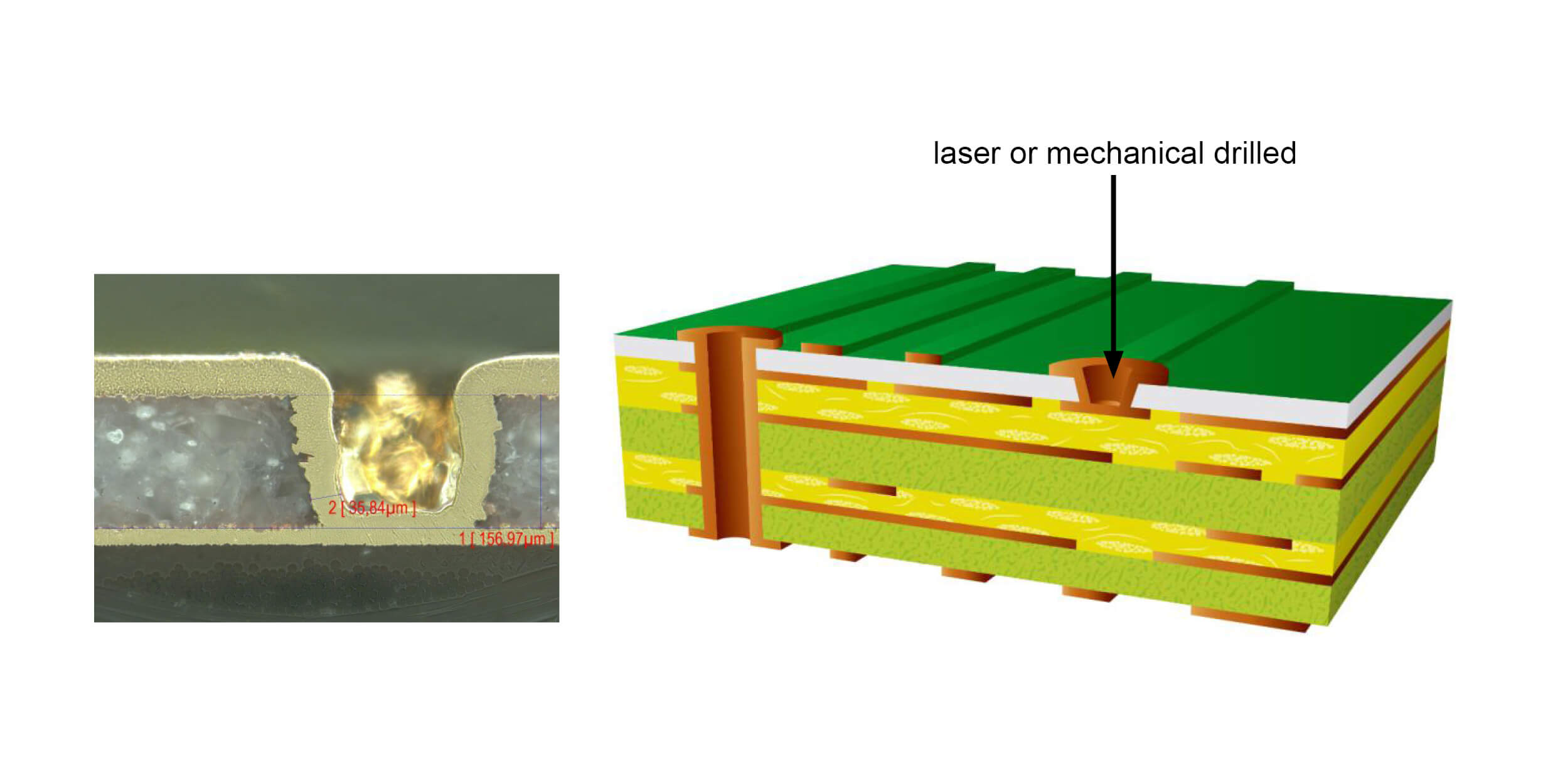

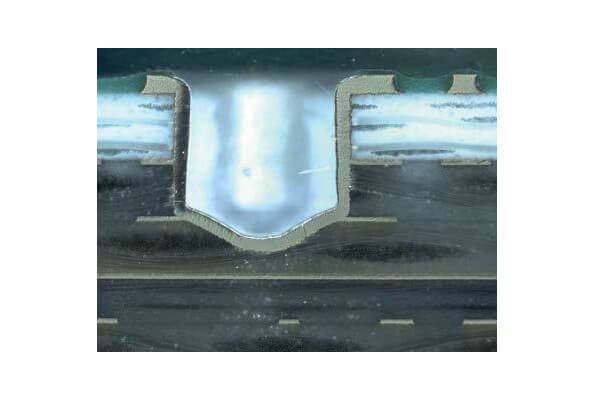

8-layer HDI PCB with blind vias as “mixed-dielectrics“ build-up

(material: HF material + FR4-TG-150°C; for a frequency range of 24 GHz)

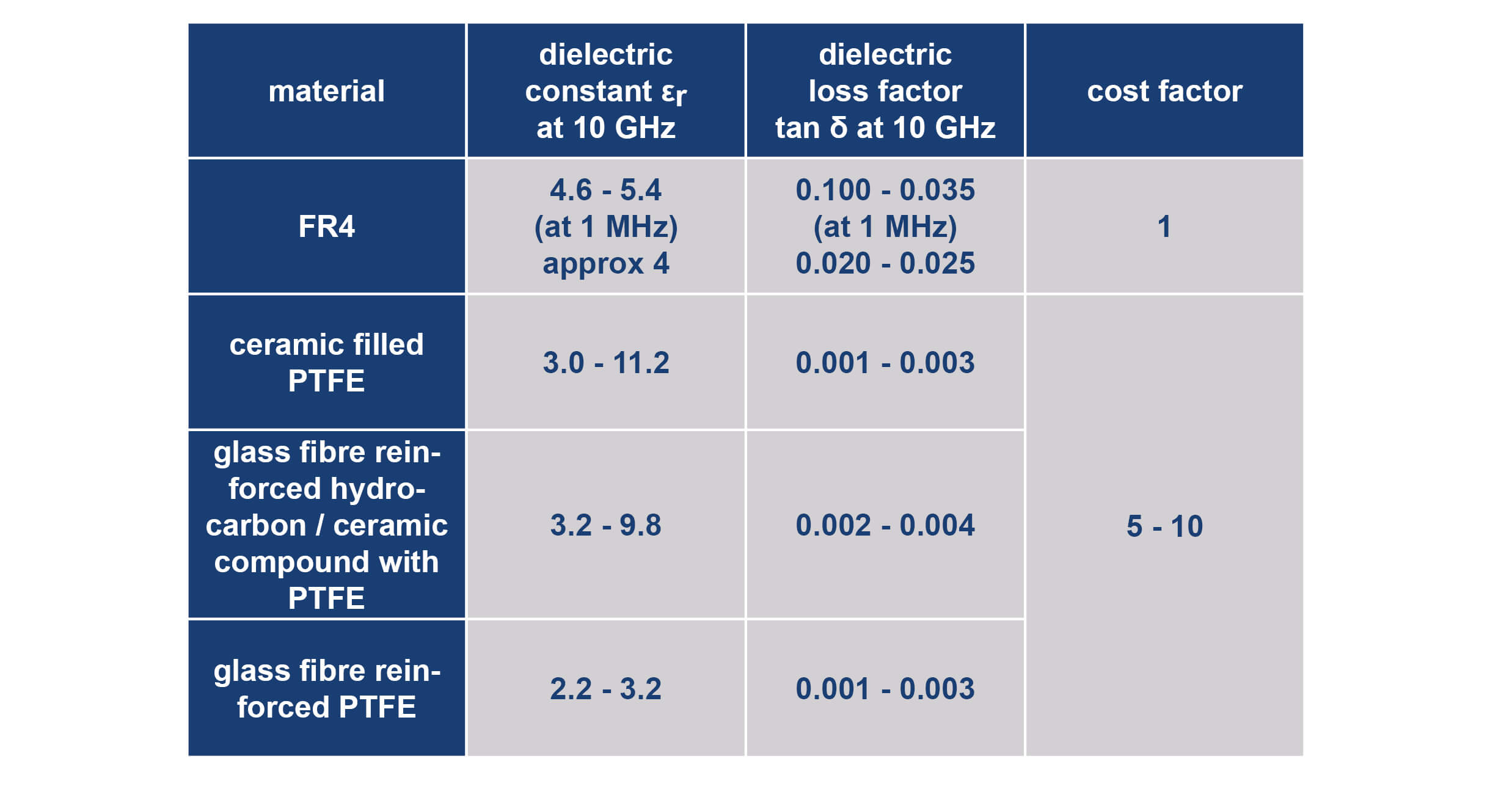

Significant factors influencing the realisation of these characteristics are the dielectric constant εr and the dielectric dissipation factor tan.

A variety of different HF materials are available for different frequency ranges:

- ceramic-filled PTFE composites

- glass-fibre reinforced hydrocarbon/ceramic compound without PTFE

- glass-fabric reinforced PTFE laminates

These materials are additionally characterised by their good thermal stability. Most HF materials are 5 to 10 times more expensive than standard epoxy materials. Therefore use HF material only where required! As good alternative use “mixed dielectrics“ constructions or “hybrid” constructions. Mixed dielectrics constructions can reduce costs if the HF dielectric is only required between a few layers and if the rest of the construction can be FR4

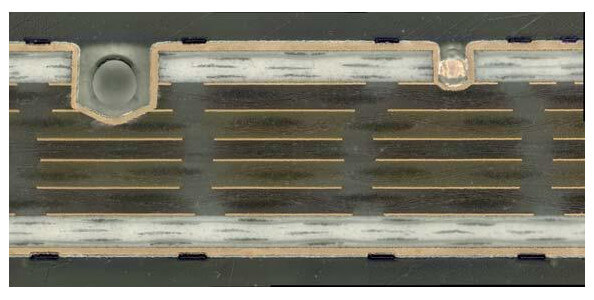

6 layers HDI mixed dielectrics PCB with blind vias

nbsp]

Advantages of the HF Base Materials we use:

- excellent mechanical characteristics for reliable multilayer design

- coefficients of expansion adapted to copper, thus enabling for instance reliable mounting of assemblies/reliability of the barrel (z expansion)

- suitable for epoxy-glass “hybrid” multilayers

- a stable dielectric constant across temperature and frequency profile

- laminates available for applications up to 77GHz

- ideal für band-pass filters, oscillators and microstrip-patch antennas

Knowhow

- impedance calculation

- layer construction

- processes adapted to use of the special HF materials

We generally recommend that you contact our expert team already before planning a HiFrequency PCB and discuss the project in detail in order to prevent avoidable problems at an early stage and to develop cost-efficient solutions.

HiFrequency PCB hydrocarbon / ceramic compound (glass-fabric reinforced) and FR4

Contact to product management:

product management

+49 (0) 2831 - 3 94-0

info@unimicron.de

Further PCB Technologies:

Thick Copper Technology - HiCu PCB | Thick Copper Profile Technology - HiCu Profile PCB | HDI Technology - HiDensity PCB | Metal Inlay Technology - Metal Inlay PCB | IMS & Heatsink Technology - Metal Plate PCB | Semiflex Technology - Semiflex PCB | Partial Thick Copper Technology - Wirelaid®